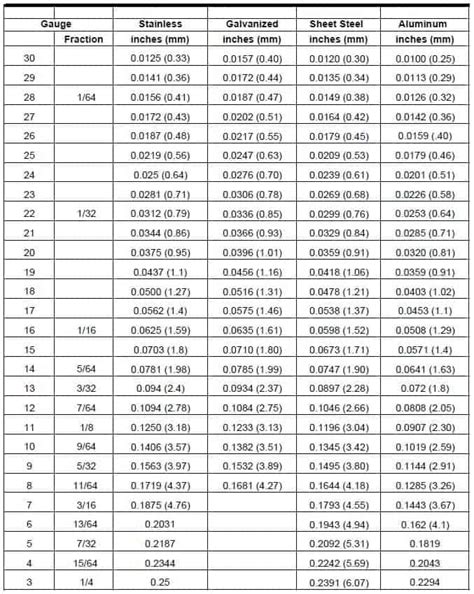

how to measure the thickness of sheet metal|sheet gauge to mm chart : custom The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter. LIVES NOVINHAS 🔥. 4 640 subscribers. View in Telegram. Preview channel. If you have Telegram, you can view and join LIVES NOVINHAS .

{plog:ftitle_list}

Resultado da 110 ótimas perguntas “quebra-gelo” para fortalecer o espírito de equipe. Neste artigo, as atividades de fortalecimento do espírito de equipe e as perguntas quebra-gelo estão .

The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.Pure metal / Used as an alloy element for aluminum, lead, zinc, and other . How to Measure Sheet Metal Thickness? There are two ways to measure sheet metal: using a measuring tape (which is less precise) and a .

After you understand a sheet metal gauge, you should learn how to measure the thickness of sheet metal. The sheet metal thickness can be measured using regular tape or a gauge wheel. #1: Measuring Sheet Metal .

The gauge of a sheet of metal is a reference to how thick it is. The higher the numbered gauge a piece of metal is, the thicker the piece is in millimeters. If you want to find out what gauge your sheet metal is, measure its thickness using a regular tape measure. Gauges are used to specify the thickness of a sheet metal. Gauges are neither standard nor metric and the values are independent of those measurement systems. A gauge conversion chart can be used to determine .

However, measuring the thickness of an individual sheet is tough. If you’re looking for a general estimate, you can use a ruler and a stack of paper to measure and calculate the thickness. Since this isn’t very precise, try using a digital caliper on a single sheet instead.

Sheet metal gauge is a fundamental measurement in metalworking that denotes the thickness of sheet metal. Originating from the Browne & Sharpe system in North America, gauge is a standardized unit used to specify the thickness of metal sheets, plates, and wire.When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the In today’s metal industry, gauge and inch measurements are both used to describe thickness. Below, we’ve outlined the distinctions between each method. Measuring Sheet Metal Using the Gauge Measurement System. When purchasing sheet metal, the thickness is typically measured via the gauge system. Unlike other measurements, gauges .

What Is a Sheet Metal Gauge? A sheet metal gauge is a standard unit of measure used to determine the thickness of a metal sheet. The gauge number and thickness have an inverse relationship – the higher the gauge number, the thinner the sheet. For instance, 10-gauge aluminum is 0.1019” thick, while 18-gauge aluminum is 0.040”How do you measure metal thickness? To accurately measure the thickness of a metal without damaging it, an ultrasonic thickness gauge should be used. What is mil thickness? A mil (or thou) is a unit of thickness that equals one thousandth of an inch (0.001 inches). Example: 10 mils = 0.010 inches. Sheet metal thickness is measured in gauges; the higher the number, the thinner the sheet metal. The most commonly-used sheet metal sizes range from 26 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool is used to measure metal thickness and shows both the gauge number as well as the thickness of the metal in thousandths of an inch.

One general rule across both though is that the higher the gauge, then the thinner the metal with the most commonly used sheet metal gauges ranging from the thinner end of the scale around 30 down (or up) to thicker sheets of around 7 gauge. Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . Our guide on how to measure screw sizes includes a screw size chart and how to convert between imperial and metric sizing. . according to the same principle: diameter x length. Here is a small example: 5 x 120 mm would mean the screw is 5 mm thick and 120 mm long. If you now want to measure a screw yourself, proceed as follows: First of all .

Large mills are automated, but some smaller mills still rely on hand-held micrometers to gauge metal thickness. AR200 laser measurement sensors are ideal for measuring steel strip thickness to fine resolutions. Steel passes between two opposing non-contact laser sensors. . The thickness measurement of a plexiglass sheet is a very common . Sheet metal gauge refers to a standardized method used to measure and categorize the thickness of sheet metal. This system, . gauging follows its own set of rules. To find out the actual thickness of sheet metal, you can refer to a gauge conversion chart. This chart helps translate gauge numbers, such as 18 gauge, into familiar measurements .

When selecting a tool for measuring the thickness of metal sheets, you should consider the range of thicknesses, the shape and size of the sheet, the surface condition and texture of the metal .Gauges are used to signify the sheet metal thickness. Using a sheet metal gauge chart, the user can easily convert the mentioned gauge into actual thicknesses in inches or mm. Steel thickness gauges can be used to verify .As you can see on the sheet metal gauge chart below, the metal gauge thickness will vary significantly depending on the metal. For instance, a sheet of 30-gauge standard steel measures 0.012 inches, which is slightly smaller than 30-gauge galvanized steel at 0.0157 inches and slightly larger than 30-gauge aluminum at 0.01 inches. Step 2: Measure Expanded Metal Thickness. Using a caliper, measure the thickness of the expanded metal sheet or panel. This will help you determine the gauge or wire diameter of the material. Expanded metal is defined by its mesh size, which refers to the distance between two adjacent strands. Measure the mesh size using a ruler or tape measure.

STK: A measurement of starting raw material thickness. Contrary to belief, the expanding process does not directly alter material thickness. Strand Thickness should not be confused with the overall height or depth of expanded metal. Typically, mesh height can be as much as 1-2 times the measurement of SWDT. How to Measure a Flattened Mesh A gauge is a unit of measurement used to measure the thickness of a flat sheet of metal. The gauge chart—a handy chart for converting gauges to other units of measurement—generally runs from 0 to 38, though it varies depending on the kind of metal used. The higher the number, the thinner the metal, and vice versa. The Gauge Chart gauge non-ferrous metal alum, brass, etc. inches galvanized steel inches standard steel inches stainless steel inches; 1.2893.2812: 2.2576.2656: 3.2294.2391.2500

Learn how to measure stamped sheet metal thickness with MTI’s Digital Accumeasure, a high-precision capacitance measurement system with nanometer accuracy and stability.. Problem. High silicon steels are alloys of iron and silicon that are easily magnetized and demagnetized. They can be supplied as sheet metal with a very thin dielectric coating. To measure the thickness of an expanded metal sheet using a gauge, place the sheet onto a flat surface with one edge resting against a flat edge, ensuring that the sheet is perpendicular to the edge. Slide the gauge’s pointer along the sheet’s surface, recording the measurement displayed on the gauge. The minimum radius also increases with harder material. For 0.25-in.-thick 6061 in a “T4” condition, the material supplier may specify the minimum radius to be 3 times the thickness; 0.375-in.-thick plate may have a minimum radius of 3.5 times the thickness; for 0.5-in.-thick plate it can be 4 times the thickness.

Paste thickness measurement after metal masking. More details. NEW. Reflective. . 2D thrubeam sensors can measure the step height between a roller and a sheet to get a thickness measurement. Additionally, A second sensor can be added to get a width measurement. Telecentric Measurement System. TM-X5000 series. View Catalog;A reversible anvil lets you adapt the gauge to the shape of the object you are measuring. Use the round face on the anvil to measure the wall thickness of pipe, tubing, and other curved surfaces. Use the flat face to measure sheet metal, paper, and other flat stock.

thickness of steel gauge chart

thickness chart for sheet metal

stainless steel thickness chart

Liv Morgan Mattel Elite Boneco Wwe Divas Total Novo Origin.

how to measure the thickness of sheet metal|sheet gauge to mm chart